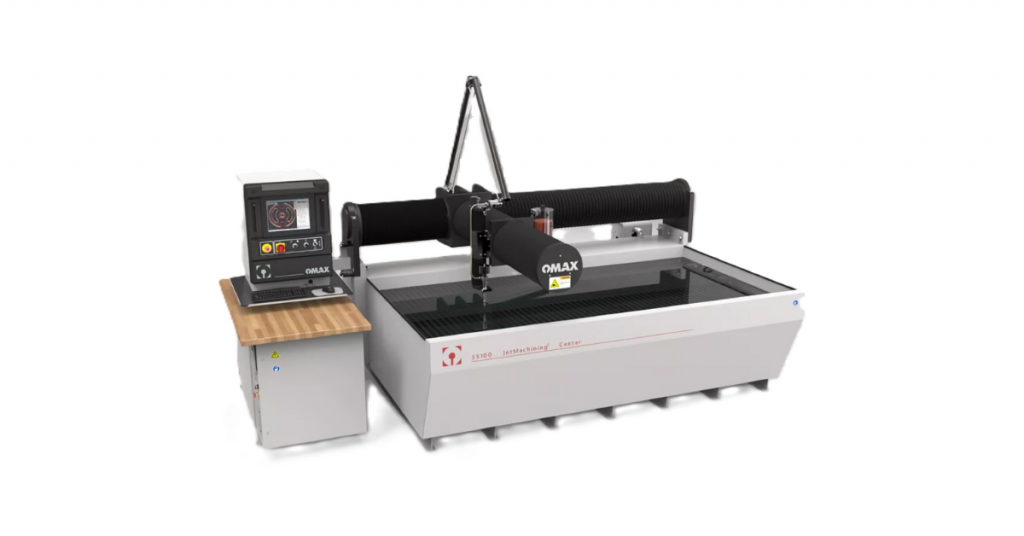

The OMAX 55100 Abrasive Water Jet is a standout in the world of precision cutting technology. Designed to deliver unparalleled accuracy and efficiency, this water jet cutting system is ideal for a wide range of applications, from intricate metalwork to delicate glass designs.

In this review, we will dive into the key features, performance, and benefits of the OMAX 55100, highlighting why it is a valuable addition to any workshop or industrial setting.

Key Features of the OMAX 55100 Abrasive Water Jet

- Precision Cutting: The OMAX 55100 offers a cutting tolerance of ±0.001″ (±0.025 mm), ensuring that even the most detailed designs are executed with exceptional accuracy.

- Large Cutting Area: With a cutting area of 10′ 0″ x 5′ 2″ (3,048 mm x 1,575 mm), the OMAX 55100 accommodates large materials, providing flexibility for various project sizes.

- High-Speed Cutting: Equipped with a high-pressure pump capable of reaching up to 60,000 psi (4,137 bar), the OMAX 55100 delivers rapid cutting speeds, reducing production time and increasing efficiency.

- Versatile Material Handling: This water jet cutter can handle a wide range of materials, including metals, composites, glass, ceramics, and plastics, making it a versatile tool for diverse applications.

- OMAX Intelli-MAX Software: The advanced Intelli-MAX software provides an intuitive interface, allowing users to easily program and control the cutting process. The software includes features like precise motion control and automatic tool path generation.

- Abrasive Management System: The integrated abrasive delivery system ensures consistent flow and optimal cutting performance. This system also minimizes abrasive waste, contributing to cost savings.

- Environmentally Friendly: Utilizing water and garnet abrasive, the OMAX 55100 produces minimal waste and operates without harmful emissions, making it an environmentally responsible choice.

Pros and Cons of the OMAX 55100 Abrasive Water Jet

Pros:

- Precision Cutting: Achieves a cutting tolerance of ±0.001″ for detailed and accurate cuts.

- Large Cutting Area: Accommodates large materials with a 10′ 0″ x 5′ 2″ cutting area.

- High-Speed Cutting: Features a high-pressure pump reaching up to 60,000 psi for fast cutting speeds.

- Versatile Material Handling: Capable of cutting various materials, including metals, composites, glass, and plastics.

- User-Friendly Software: Intelli-MAX software simplifies programming and operation with intuitive controls.

Cons:

- Initial Investment: The high upfront cost may be a barrier for small businesses.

- Maintenance Requirements: Regular maintenance is necessary to ensure optimal performance and longevity.

Performance and Efficiency

The OMAX 55100’s performance is marked by its ability to cut through various materials with remarkable precision and speed. The high-pressure pump, coupled with the abrasive management system, ensures that cuts are clean and smooth, reducing the need for secondary finishing processes. This efficiency not only saves time but also reduces operational costs, making the OMAX 55100 a cost-effective solution for businesses.

One of the standout aspects of the OMAX 55100 is its ability to handle complex geometries and intricate designs. The precision cutting capabilities are enhanced by the Intelli-MAX software, which allows users to create detailed patterns and shapes with ease. This feature is particularly beneficial for industries that require high levels of accuracy, such as aerospace, automotive, and manufacturing.

User Experience

Operators of the OMAX 55100 often praise its user-friendly interface and ease of operation. The Intelli-MAX software is designed to streamline the cutting process, offering features like automatic tool path generation and precise motion control. This intuitive interface reduces the learning curve for new users and enhances productivity for experienced operators.

The large cutting area of the OMAX 55100 also receives positive feedback, as it allows for the handling of large sheets of material without the need for multiple setups. This capability is especially useful for projects that require consistency across large dimensions, such as architectural components and large-scale fabrication.

Versatility and Applications

The versatility of the OMAX 55100 is one of its key strengths. Its ability to cut through a wide range of materials opens up numerous possibilities for various industries. For instance:

- Metal Fabrication: The OMAX 55100 excels in cutting metals such as steel, aluminum, and titanium with precision, making it ideal for creating machine parts, brackets, and custom components.

- Glass and Ceramics: The water jet’s gentle cutting action is perfect for delicate materials like glass and ceramics, ensuring clean edges without cracking or chipping.

- Composites and Plastics: The OMAX 55100 handles composites and plastics with ease, making it suitable for producing components for aerospace, automotive, and consumer goods industries.

- Custom Signage and Art: The precision and flexibility of the OMAX 55100 make it a favorite among artists and designers for creating custom signage, sculptures, and intricate art pieces.

Environmental Impact

In addition to its impressive performance, the OMAX 55100 is also an environmentally friendly option. The use of water and garnet abrasive results in minimal waste, and the absence of harmful emissions makes it a cleaner alternative to traditional cutting methods. This eco-friendly aspect is increasingly important in today’s industrial landscape, where sustainability is a key consideration.

Economic Considerations

Investing in the OMAX 55100 Abrasive Water Jet can yield significant economic benefits for businesses. The machine’s efficiency in cutting reduces material waste and minimizes the need for secondary finishing processes, leading to cost savings. Additionally, the versatility of the OMAX 55100 allows companies to take on a wider range of projects, potentially increasing revenue streams.

The initial investment in the OMAX 55100 is justified by its long-term benefits, including reduced operational costs, increased productivity, and the ability to deliver high-quality products consistently.

For businesses in competitive industries, the precision and reliability of the OMAX 55100 can provide a distinct advantage.

Conclusion

The OMAX 55100 Abrasive Water Jet stands out as a powerful, versatile, and precise cutting solution. Its ability to handle a wide range of materials with exceptional accuracy makes it an invaluable tool for various industries. The integration of advanced features like the Intelli-MAX software and the abrasive management system enhances its performance and user experience, while its environmentally friendly operation aligns with modern sustainability standards.

For businesses looking to invest in a reliable and efficient cutting system, the OMAX 55100 offers a compelling combination of precision, versatility, and eco-friendliness. Whether you are in metal fabrication, custom art, or any industry requiring detailed and accurate cuts, the OMAX 55100 is a worthy addition to your arsenal. Its robust construction, ease of maintenance, and comprehensive customer support further solidify its position as a top choice for precision cutting needs.

Frequently Asked Questions About the OMAX 55100 Abrasive Water Jet

What materials can the OMAX 55100 cut?

- The OMAX 55100 can cut metals, composites, glass, ceramics, and plastics.

How precise is the OMAX 55100 Abrasive Water Jet?

- It offers a cutting tolerance of ±0.001″, ensuring exceptional accuracy.

What is the size of the cutting area?

- The cutting area is 10′ 0″ x 5′ 2″ (3,048 mm x 1,575 mm), suitable for large materials.

How fast can the OMAX 55100 cut materials?

- The high-pressure pump, reaching up to 60,000 psi, allows for rapid cutting speeds.

Is the OMAX 55100 environmentally friendly?

- Yes, it uses water and garnet abrasive, producing minimal waste and no harmful emissions.

What software does the OMAX 55100 use?

- The OMAX 55100 uses Intelli-MAX software, which provides an intuitive interface for programming and control.

What industries benefit from using the OMAX 55100?

- Industries such as aerospace, automotive, manufacturing, and custom art benefit from its precision and versatility.

Related Searches/Variations of the OMAX 55100 Abrasive Water Jet

- OMAX 55100 Water Jet Cutter

- OMAX 55100 Abrasive Water Jet Machine

- OMAX 55100 High-Pressure Water Jet

- OMAX 55100 Industrial Water Jet Cutter

- OMAX 55100 Precision Cutting System

- OMAX 55100 Versatile Water Jet

- OMAX 55100 Metal Cutting Water Jet

- OMAX 55100 Glass Cutting Water Jet

- OMAX 55100 Large Format Water Jet

- OMAX 55100 Intelli-MAX Software Water Jet