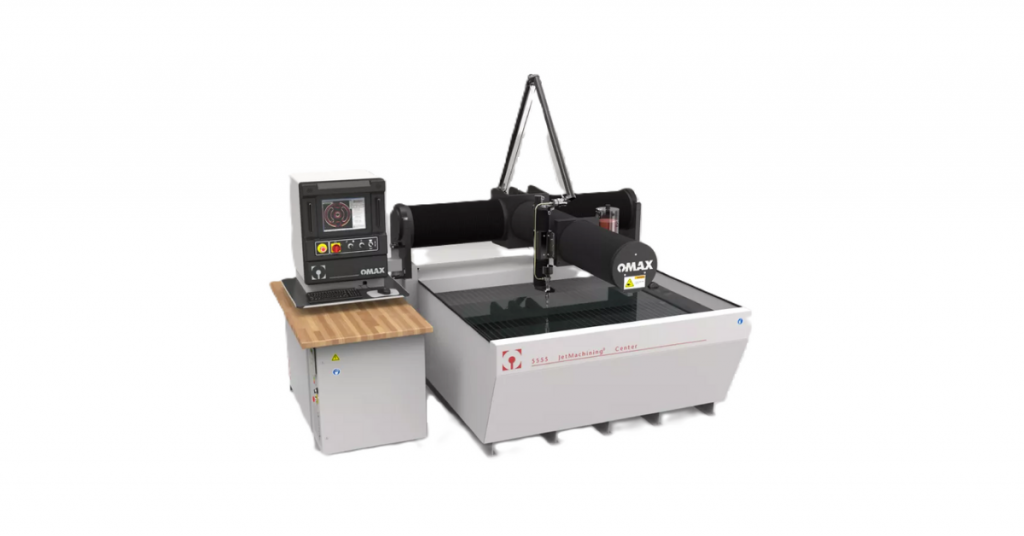

The OMAX 5555 Abrasive Water Jet is a versatile and powerful tool, designed to meet the demands of modern machining with precision and efficiency. This review dives into the key features, performance, and benefits of the OMAX 5555, showcasing why it stands out in the competitive market of abrasive water jets.

Key Features of the OMAX 5555 Abrasive Water Jet

- Precision Cutting: Delivers high-accuracy cuts for intricate designs and complex shapes across various materials.

- Versatile Material Handling: Efficiently cuts metals, composites, stone, glass, and more, suitable for multiple industries.

- Intelli-MAX Software Suite: User-friendly software provides precise control, optimizing speed and performance.

- Efficient Pump Technology: Advanced pump design ensures consistent high-pressure cutting, reducing energy consumption and maintenance costs.

- Robust Build Quality: Durable construction and high-quality components ensure long-term reliability and minimal downtime.

Pros and Cons of the OMAX 5555 Abrasive Water Jet

Pros:

- High Precision: Delivers accurate and clean cuts for intricate designs.

- Material Versatility: Cuts a wide range of materials including metals, composites, stone, and glass.

- User-Friendly Software: Intelli-MAX software optimizes cutting performance and is easy to use.

- Efficient and Reliable: Advanced pump technology reduces energy consumption and maintenance costs.

- Durable Build: Robust construction ensures long-term reliability and minimal downtime.

Cons:

- Initial Cost: High initial investment compared to other cutting technologies.

- Space Requirement: Requires a significant amount of space for installation and operation.

Key Features of the OMAX 5555 Abrasive Water Jet

Precision Cutting

The OMAX 5555 is engineered for high-precision cutting, capable of handling intricate designs and complex shapes. The machine uses a high-pressure stream of water mixed with abrasive particles to cut through various materials with exceptional accuracy. This ensures minimal waste and a high-quality finish, making it ideal for industries requiring detailed and precise cuts.

Versatility in Material Handling

One of the standout features of the OMAX 5555 is its ability to cut a wide range of materials. From metals and composites to stone and glass, this water jet handles it all with ease. This versatility is crucial for industries such as aerospace, automotive, and manufacturing, where diverse materials are used.

Intelli-MAX Software Suite

The OMAX 5555 is equipped with the Intelli-MAX Software Suite, a user-friendly and powerful software package that enhances the machine’s capabilities. This software provides precise control over the cutting process, optimizing speed and performance while ensuring high-quality results. The intuitive interface makes it accessible for operators of all skill levels.

Efficient Pump Technology

The OMAX 5555 features advanced pump technology that delivers high-pressure water for cutting. The efficient pump design reduces energy consumption and maintenance costs while ensuring consistent performance. This translates to lower operating costs and increased productivity for businesses.

Robust Build Quality

Constructed with durability in mind, the OMAX 5555 boasts a robust frame and components that withstand the rigors of heavy use. The high-quality materials and meticulous engineering ensure long-term reliability and minimal downtime, which is essential for maintaining production schedules.

Large Cutting Area

The OMAX 5555 offers a generous cutting area of 55” x 55”, providing ample space for handling large sheets of material. This large workspace accommodates a variety of projects, from small, intricate parts to larger components, enhancing the machine’s versatility.

Environmental Considerations

Water jet cutting is an environmentally friendly process, as it does not produce harmful fumes or waste materials. The OMAX 5555 supports sustainable practices, helping businesses reduce their environmental footprint. The closed-loop system minimizes water usage, and the abrasive materials used can often be recycled.

Performance and Usability

The OMAX 5555 excels in both performance and usability, making it a top choice for professionals in various industries. Its precision and versatility allow for seamless integration into existing workflows, while the intuitive software ensures that operators can quickly become proficient in using the machine.

Cutting Speed and Efficiency

The OMAX 5555 delivers impressive cutting speeds, significantly reducing the time required to complete projects. The high-pressure water stream, combined with the efficient pump technology, ensures that even the toughest materials are cut swiftly and accurately. This efficiency translates to higher throughput and increased profitability for businesses.

Ease of Use

Despite its advanced capabilities, the OMAX 5555 is designed with user-friendliness in mind. The Intelli-MAX Software Suite simplifies the process of setting up and executing cuts, allowing operators to focus on optimizing production. The machine’s interface is straightforward, and the software includes features such as automated tool path generation and real-time cutting simulation.

Maintenance and Durability

Maintaining the OMAX 5555 is relatively straightforward, thanks to its robust design and high-quality components. Regular maintenance tasks, such as changing the abrasive and checking the water filter, are simple and quick to perform. The machine’s durability ensures that it remains operational for extended periods, reducing the need for costly repairs or replacements.

Benefits for Businesses

Investing in the OMAX 5555 Abrasive Water Jet offers numerous benefits for businesses across various sectors.

Cost Savings

The efficiency and precision of the OMAX 5555 result in significant cost savings. Reduced material waste, lower energy consumption, and minimal maintenance expenses all contribute to a lower total cost of ownership. Additionally, the machine’s high-speed cutting capabilities enhance productivity, allowing businesses to complete more projects in less time.

Versatility and Adaptability

The ability to cut a wide range of materials with a single machine is a major advantage. Businesses no longer need to invest in multiple cutting tools, as the OMAX 5555 can handle diverse materials with ease. This versatility makes it an excellent choice for industries that work with various substrates.

Quality and Precision

The high level of precision offered by the OMAX 5555 ensures that every cut is accurate and clean, resulting in superior-quality products. This precision is particularly important in industries where tolerances are tight and the quality of the final product is paramount.

Environmental Responsibility

By opting for the OMAX 5555, businesses can demonstrate their commitment to environmental sustainability. The water jet cutting process is cleaner and more environmentally friendly compared to other cutting methods, helping companies reduce their ecological impact.

Advanced Technology and Innovations

Precision Control with Intelli-TRAX® Drive System

The OMAX 5555 incorporates the Intelli-TRAX® drive system, which ensures precise and smooth movement of the cutting head. This system uses linear encoders to provide accurate feedback to the control system, enabling consistent and repeatable precision. This feature is crucial for applications requiring tight tolerances and intricate designs.

A-Jet® Cutting Head

For enhanced versatility, the OMAX 5555 can be equipped with the A-Jet® cutting head, allowing for angled cuts and bevels. This addition broadens the scope of potential applications, from creating complex shapes to preparing weld-ready edges. The A-Jet® is capable of cutting at angles up to 60 degrees, providing significant flexibility in cutting operations.

EnduroMAX® Pump Technology

The EnduroMAX® pump is a standout feature, offering high efficiency and reliability. This pump is designed to provide a consistent flow of high-pressure water, enhancing cutting performance while minimizing maintenance requirements. The advanced design of the EnduroMAX® pump also extends its lifespan, contributing to lower long-term operational costs.

Practical Applications and Industry Use Cases

Aerospace Industry

In the aerospace industry, precision and material versatility are paramount. The OMAX 5555’s ability to cut lightweight composites, titanium, and other aerospace materials with high precision makes it an indispensable tool. Its capacity to produce complex parts with tight tolerances ensures that aerospace components meet stringent industry standards.

Automotive Manufacturing

The automotive industry benefits from the OMAX 5555’s capability to handle various materials, including aluminum, steel, and composite panels. Its precision cutting allows for the creation of intricate components such as engine parts, brackets, and custom interior pieces. The machine’s speed and accuracy improve production efficiency, reducing lead times.

Architectural and Artistic Projects

For architectural and artistic applications, the OMAX 5555 offers unparalleled precision and creative freedom. Architects and artists can utilize the machine to cut intricate patterns in materials like marble, glass, and metal. This enables the production of detailed architectural elements, sculptures, and custom installations that require high precision and aesthetic quality.

Enhanced User Experience

Intelli-VISOR® Monitoring System

The Intelli-VISOR® monitoring system enhances the user experience by providing real-time diagnostics and performance data. This system alerts operators to potential issues before they become critical, ensuring uninterrupted operation and reducing downtime. By monitoring key parameters such as pump pressure, abrasive levels, and cutting performance, operators can maintain optimal machine performance.

Training and Support

OMAX provides comprehensive training and support to ensure that users can fully utilize the capabilities of the 5555 Abrasive Water Jet. From initial setup and training sessions to ongoing technical support, OMAX ensures that operators have the knowledge and resources needed to maximize the machine’s potential. This commitment to customer support enhances the overall user experience and helps businesses achieve their production goals.

Safety Features

Safety is a critical consideration in any machining environment. The OMAX 5555 incorporates various safety features, including emergency stop buttons, protective covers, and automatic shutdown protocols. These features ensure a safe operating environment, protecting both operators and the machine.

Environmental and Economic Impact

Water and Abrasive Recycling

The OMAX 5555 supports water and abrasive recycling systems, which significantly reduce waste and operational costs. By recycling water, businesses can minimize their water consumption, aligning with sustainable practices. Similarly, the ability to recycle abrasive materials reduces the need for continuous purchasing, providing economic and environmental benefits.

Energy Efficiency

The machine’s efficient pump technology and intelligent design contribute to lower energy consumption. The EnduroMAX® pump, in particular, is designed for energy efficiency, reducing the overall carbon footprint of the machining process. This energy efficiency not only benefits the environment but also translates to cost savings for businesses.

Customer Testimonials and Case Studies

Customer Success Stories

Numerous customers have reported significant improvements in their production processes after integrating the OMAX 5555 into their operations. For example, a leading aerospace manufacturer highlighted the machine’s ability to reduce production times by 30%, while maintaining the highest quality standards. Another customer in the architectural field praised the machine’s precision and ability to handle complex designs, enabling the creation of award-winning installations.

Real-World Applications

Case studies demonstrate the OMAX 5555’s versatility and effectiveness in real-world applications. A case study involving a custom metal fabrication shop revealed that the machine not only improved production efficiency but also expanded the range of services the shop could offer. By cutting previously challenging materials, the shop could take on more diverse and lucrative projects.

Conclusion

The OMAX 5555 Abrasive Water Jet is a cutting-edge tool that delivers precision, versatility, and efficiency across various industries. Its advanced technology, robust design, and user-friendly features make it an invaluable asset for businesses aiming to enhance their production capabilities.

The machine’s ability to handle a wide range of materials, coupled with its environmental and economic benefits, positions it as a top choice in the market.

Frequently Asked Questions about the OMAX 5555 Abrasive Water Jet

What materials can the OMAX 5555 cut?

- The OMAX 5555 can cut metals, composites, stone, glass, and more.

How accurate is the OMAX 5555?

- The OMAX 5555 delivers high-precision cuts with minimal waste.

Is the software easy to use?

- Yes, the Intelli-MAX software suite is user-friendly and provides precise control over the cutting process.

What are the maintenance requirements?

- Regular maintenance tasks include changing the abrasive and checking the water filter, which are simple and quick to perform.

Is the OMAX 5555 environmentally friendly?

- Yes, it supports water and abrasive recycling systems, reducing waste and operational costs.

Related Searches/Variations of the OMAX 5555 Abrasive Water Jet

- OMAX 55100 Abrasive Water Jet

- OMAX 60120 Abrasive Water Jet

- OMAX 2626 Abrasive Water Jet

- OMAX 80160 Abrasive Water Jet

- OMAX 1530 Abrasive Water Jet